-

Tel : +8618150976625

-

Email : Hello@MicrofiberLeather.com

Tel : +8618150976625

Email : Hello@MicrofiberLeather.com

I define leather fabric as a natural material created from tanned animal skin. I see leather as a symbol of both strength and elegance. It stands out for its durability, flexibility, and luxurious finish. Most leather comes from cows, goats, or sheep. I often encounter leather in fashion, furniture, and automotive interiors. The automotive industry values leather for its comfort and premium look. In 2024, the global leather market reached $93.33 billion, driven by strong demand in car upholstery and a growing interest in sustainable options.

Leather fabric is made from tanned animal hides, primarily from cows, goats, and sheep, and is known for its durability and elegance.

The tanning process transforms raw hides into a flexible material, making leather resistant to decay and suitable for various uses.

Full-grain leather is the highest quality, retaining natural imperfections and developing a rich patina over time, making it ideal for luxury goods.

Regular cleaning and conditioning are essential for maintaining leather's appearance and longevity; avoid harsh chemicals and over-conditioning.

Sustainable leather alternatives, such as Piñatex and mushroom leather, are gaining popularity due to their lower environmental impact.

Leather's natural breathability and comfort make it a preferred choice for fashion, furniture, and automotive interiors.

Understanding the different types of leather, like top-grain and split leather, helps in selecting the right material for specific projects.

Proper storage and care can significantly extend the lifespan of leather products, ensuring they remain functional and beautiful.

When I answer the question "what is leather," I describe it as a material made from tanned animal hides. I see leather fabric as the result of transforming raw animal skins into a durable and flexible material through a process called tanning. This process changes the structure of the hide, making it resistant to decay and suitable for a wide range of uses. I often compare leather fabric to untreated animal hides to highlight the differences. The table below shows how leather fabric stands apart from raw hides:

|

Characteristic |

Leather |

Untreated Animal Hide |

|---|---|---|

|

Material Type |

Tanned animal skins and hides |

Raw animal skins and hides |

|

Flexibility |

Strong, flexible, and durable |

Hard and inflexible when dried |

|

Decay Prevention |

Prevented through tanning |

Can putrefy when rewetted |

I recognize that leather fabric is not just preserved skin. The tanning process gives it unique properties that make it valuable in many industries. When I touch leather, I notice its strength and flexibility, which set it apart from untreated animal hides.

I value leather fabric for its combination of natural and functional qualities. Several features make it unique compared to other materials:

Leather fabric has a fibrous texture that provides strength and durability.

I see irregular pore patterns on the surface, which vary depending on the animal source.

The thickness and flexibility of leather fabric come from natural elastin fibers, making it hard for synthetic materials to match.

Leather fabric breathes naturally, allowing air and moisture to pass through. This quality adds comfort, especially in clothing and upholstery.

Over time, leather fabric develops a patina, a rich surface character that synthetic alternatives cannot replicate.

Tip: I always recommend leather fabric for products that need to last and look better with age. Its ability to age gracefully and develop character makes it a favorite in my work.

I also notice that leather fabric stands out for its timeless appeal and versatility. It remains stylish across generations and adapts to many uses, from fashion to interiors. I appreciate how it combines durability, flexibility, and a classic look. Leather fabric resists wear, allows air and moisture exchange, and develops a unique patina over time.

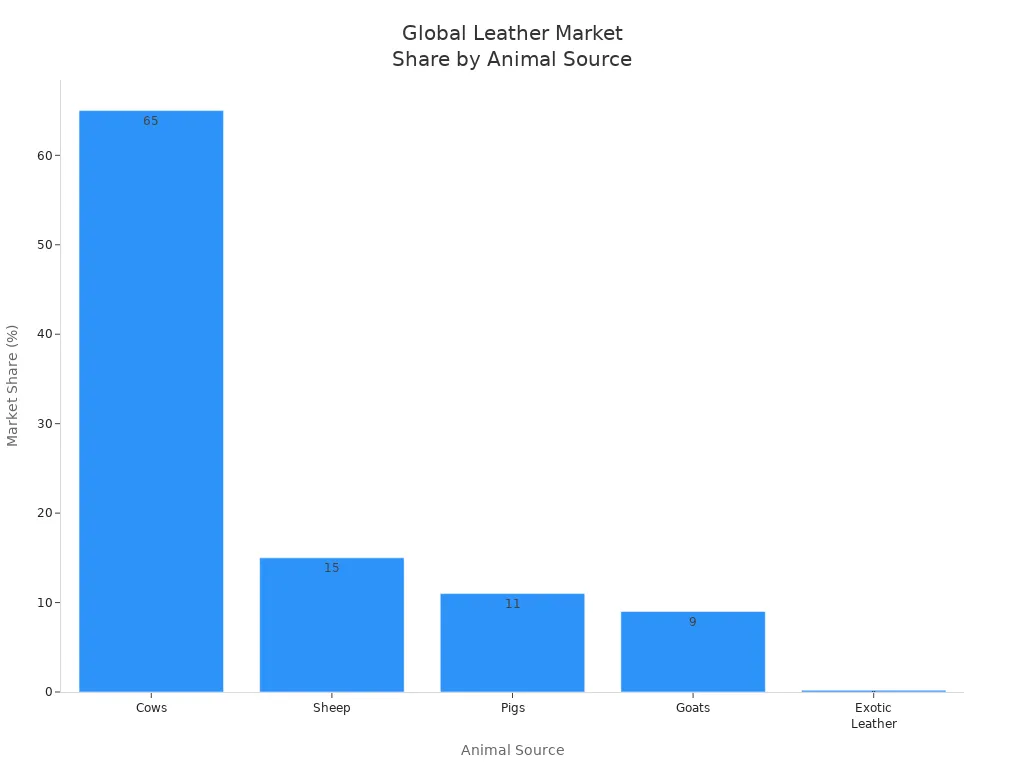

When I select leather fabric for a project, I consider the animal source because it affects the texture, strength, and appearance. Most leather fabric comes from a few main animals. The table below shows the global market share for each source:

|

Animal Source |

Market Share (%) |

|---|---|

|

Cows |

65 |

|

Sheep |

15 |

|

Pigs |

11 |

|

Goats |

9 |

|

Exotic Leather |

<0.2 |

I use cowhide most often because it offers the best balance of durability and availability. Sheep and goat leather fabric provide a softer feel, which I prefer for clothing and accessories. Pigskin is common in some regions and offers a unique texture. Exotic leather, such as from reptiles or ostriches, makes up a tiny fraction of the market but adds luxury to specialty items.

When I choose leather fabric, I always think about the qualities each animal source brings. Cow leather fabric works well for furniture and automotive interiors. Sheep and goat leather fabric suit fashion and accessories. Each type of animal hide gives leather fabric its own character and performance.

When I work with leather fabric, I always follow a structured production process. This process transforms raw hides into a finished material that meets strict quality standards. I break down the leather making process into three main stages: raw hide selection, tanning, and finishing techniques. Each step plays a critical role in determining the final quality, durability, and appearance of the leather.

|

Step |

Description |

|---|---|

|

Preparatory stages |

I prepare the hide for tanning by removing unwanted components and treating the skin. |

|

Tanning |

I convert raw hide into a stable material suitable for various applications, preventing putrefaction. |

|

Crusting |

I thin, retan, and lubricate the hide, often including coloring operations. |

|

Surface coating |

I apply finishing operations to enhance the leather's appearance and durability. |

I always start by selecting the best hides for leather fabric production. The quality of the hides directly impacts the final product. I look for hides with minimal damage to the grain surface. Proper handling during transport and slaughter is essential. I avoid hides with marks from parasites or poor handling. After tanning, I assess natural imperfections to ensure only the best hides move forward.

I check for damage to the grain surface.

I consider how the hides were handled during transport and slaughter.

I inspect for natural imperfections after tanning.

I reject hides with damage from parasites or poor handling.

Note: High-quality hides lead to superior leather fabric. I never compromise on this step because it sets the foundation for the entire production process.

Tanning is the heart of leather fabric production. I use this step to stabilize the hides and prevent decay. The tanning process changes the protein structure of the hides, making them durable, flexible, and suitable for many uses. I rely on different tanning methods depending on the desired characteristics of the leather.

The leather industry mainly uses three tanning methods: chrome tanning, vegetable tanning, and non-chrome tanning. Chrome tanning offers speed and efficiency. It produces flexible and water-resistant leather, but I remain aware of its environmental concerns due to the toxicity of chromium compounds. Vegetable tanning, the oldest method, uses natural plant materials. This method creates high-quality leather that develops a unique patina over time, though it may be less water-resistant. Non-chrome tanning includes various alternative processes, but I focus on the two most common methods in my work.

I use vegetable tanning when I want leather fabric with a natural look and feel. This method relies on tannins from plants such as oak, chestnut, or mimosa. Vegetable tanning takes several weeks. The process produces leather that is firm, develops a rich patina, and ages beautifully. I recommend vegetable-tanned leather for products like saddles, belts, and high-end accessories. The natural process appeals to clients who value tradition and sustainability.

Chrome tanning dominates the modern leather industry. I choose this method when I need soft, flexible, and water-resistant leather fabric. Chrome tanning uses chromium salts and finishes in a matter of days. The resulting leather is ideal for fashion, upholstery, and automotive interiors. However, I always consider the environmental impact. Chrome tanning generates hazardous waste and poses health risks to workers. I take extra precautions to manage waste and protect the environment.

Warning: The tanning process uses up to 2.5 kg of chemicals and 250 liters of water for every kilogram of leather produced. This creates significant pollution and health risks for workers and nearby communities.

After tanning, I apply finishing techniques to enhance the durability and appearance of leather fabric. These techniques include edge binding, piping, burnishing, edge paint, edge dye, and edge beveling. Edge binding and piping reinforce the edges, making them more durable for items that face heavy use. Burnishing smooths and polishes the edges, giving a glossy finish. Edge dyeing adds color and depth, improving visual appeal. I select finishing methods based on the intended use and desired look of the leather.

Tip: Mastering finishing techniques allows me to tailor leather fabric for specific projects, balancing durability and aesthetics.

I always pay close attention to each stage of the production process. Careful selection of hides, the right tanning methods, and expert finishing ensure that the leather fabric I produce meets the highest standards. This approach guarantees a product that is both beautiful and long-lasting.

When I look for the best quality leather fabric, I always choose full-grain. This type of leather fabric comes from the topmost layer of the hide. It keeps all the natural marks, scars, and wrinkles. I appreciate these imperfections because they show the authenticity of the leather. Full-grain leather fabric stands out for its strength and durability. I have seen it last for decades when cared for properly. Over time, it develops a rich patina, which gives it a unique, glossy sheen that imitation materials cannot match.

Here is a comparison that highlights why I consider full-grain the best quality leather fabric:

|

Feature |

Full-Grain Leather |

Genuine Leather |

|---|---|---|

|

Natural Texture |

Retains original texture with imperfections |

Heavily processed for uniformity |

|

Durability |

Highly durable, can last decades |

Limited lifespan, less durable |

|

Patina Development |

Develops a rich patina over time |

Lacks significant patina development |

|

Breathability |

Naturally breathable |

Less breathable due to treatments |

|

Water Resistance |

Good water resistance |

Generally less water resistant |

|

Cost |

More expensive |

Economically priced |

Displays unique marks and scars.

Can last for decades with proper care.

Develops a rich, glossy patina.

Allows moisture and air circulation.

Offers good resistance to water.

I always recommend full-grain leather fabric for luxury goods, high-end furniture, and premium accessories. Imitation products cannot deliver the same character or longevity.

Top-grain leather fabric is another excellent choice when I want a balance between quality and a more uniform appearance. Manufacturers sand away the outermost surface to remove imperfections. This process gives top-grain leather a smoother look and feel. I find it softer and more flexible than full-grain, which makes it ideal for fashion and upholstery. Top-grain leather fabric still comes from the top layer of the hide, so it maintains much of the strength and durability I expect from the best quality leather fabric.

Here is a table that shows how top-grain compares to genuine leather:

|

Feature |

Top-Grain Leather |

Genuine Leather |

|---|---|---|

|

Quality |

Higher quality, made from the top layer of the hide. |

Lower quality, made from leftover layers of hide. |

|

Appearance |

More uniform with fewer natural markings. |

Inconsistent appearance with natural variations. |

|

Softness and Feel |

Softer and more luxurious feel. |

Stiffer and less supple. |

|

Durability |

More durable and ages well. |

Less durable, shows wear more quickly. |

I often select top-grain leather fabric for products that need a refined look but still require durability. Imitation materials may look similar at first, but they cannot match the feel or performance of real top-grain leather.

Genuine leather fabric is a term I see used often, but it does not always mean high quality. Manufacturers make genuine leather from the layers of hide left after removing the top. They process and treat it heavily to create a uniform appearance. This type of leather fabric costs less and offers a more consistent look, but it lacks the durability and character of full-grain or top-grain. I notice that genuine leather does not develop a rich patina and tends to wear out faster. Imitation products sometimes try to mimic genuine leather, but even genuine leather falls short of the best quality leather fabric.

When I choose leather fabric for a project, I always consider the types of leather available. Full-grain and top-grain offer the best quality and performance. Genuine leather provides an affordable option, but I reserve it for items where cost matters more than longevity.

When I work with split leather, I focus on the inner layers of the hide. Manufacturers create split leather by separating the top grain from the lower layers. This process results in a material that is thinner and less durable than full-grain or top-grain leather. I often use split leather fabric for products that do not require the highest strength, such as budget-friendly furniture or accessories.

Split leather fabric offers a smooth surface after finishing. The texture feels more uniform, but it lacks the natural markings found in higher-quality types of leather. I notice that split leather absorbs dyes and finishes well, which allows for a wide range of colors and effects. However, it does not develop a rich patina over time. I recommend split leather fabric for items where cost is a priority and heavy wear is unlikely.

|

Feature |

Split Leather Fabric |

Full-Grain Leather Fabric |

|---|---|---|

|

Durability |

Moderate |

High |

|

Texture |

Smooth, less natural |

Natural, unique |

|

Cost |

Lower |

Higher |

|

Patina Development |

Minimal |

Rich, develops over time |

Note: I always advise clients to choose split leather fabric for decorative pieces rather than high-traffic items. The lower cost makes it accessible, but the performance does not match premium types of leather.

I often select suede and nubuck when I want a soft, velvety finish. Both types of leather fabric come from split leather, but the finishing process sets them apart. Suede results from buffing the inner side of the hide, creating a plush texture. Nubuck, on the other hand, comes from sanding the outer layer, which gives it a finer, more durable nap.

Suede leather fabric feels soft and flexible. I use it for shoes, jackets, and accessories that require comfort and style. Nubuck offers a similar feel but with greater strength and resistance to wear. I prefer nubuck for products that need both luxury and durability, such as premium footwear and upholstery.

Here is a quick comparison:

|

Attribute |

Suede Leather Fabric |

Nubuck Leather Fabric |

|---|---|---|

|

Source |

Inner split |

Outer split |

|

Texture |

Velvety, plush |

Fine, soft nap |

|

Durability |

Moderate |

Higher |

|

Common Uses |

Shoes, jackets |

Footwear, upholstery |

Tip: I always recommend regular care for suede and nubuck leather fabric. These types of leather absorb stains easily, so I suggest using protective sprays and gentle cleaning methods.

When I encounter bonded leather, I recognize it as a composite material rather than a natural leather type. Manufacturers create bonded leather fabric from leftover leather scraps. They mix these scraps with a polyurethane binding agent and adhere the mixture to a paper backing. This process distinguishes bonded leather from other types of leather, which use whole animal hides and undergo a more intricate tanning process.

Bonded leather fabric contains about 10% to 20% genuine leather. The scraps receive treatment to resemble the texture of real leather. I see bonded leather used in budget furniture, book covers, and accessories where appearance matters more than longevity. The cost is lower, but the durability and feel do not match natural leather fabric.

Bonded leather is created from leftover leather scraps.

These scraps are mixed with a polyurethane binding agent.

The mixture is then adhered to a paper backing.

I always inform clients that bonded leather fabric offers an affordable alternative, but it does not provide the same performance or lifespan as other types of leather. The manufacturing process makes it less breathable and more prone to peeling or cracking over time.

Warning: I advise caution when choosing bonded leather fabric for high-use items. The material may look appealing at first, but it often shows wear quickly and cannot be restored like natural leather.

When I evaluate the properties of leather fabric, durability always stands out as a defining feature. I rely on leather for products that must withstand daily wear and tear. The durability of leather comes from its dense fiber structure, which resists stretching, tearing, and abrasion. I often test leather using several scientific methods to ensure it meets industry standards:

Abrasion testing simulates repeated rubbing or folding to measure how well leather resists surface damage.

Tear testing determines the force needed to start and extend a tear, which helps me assess how leather will perform under stress.

Colorfastness testing checks if leather retains its color after exposure to washing or light, which is crucial for maintaining its appearance over time.

I have seen leather outlast many synthetic materials, especially in high-traffic applications like furniture and automotive interiors. The durability of leather means that well-made products can last for decades with proper care. I always recommend leather for clients who want long-term value and reliability.

Tip: I advise regular maintenance to maximize the durability of leather. Simple cleaning and conditioning routines help preserve its strength and appearance.

Flexibility is another property I value highly in leather. This quality allows leather to adapt to different shapes and uses, from soft jackets to structured bags. The flexibility of leather depends on several factors:

The type of animal hide used influences how soft or stiff the leather feels.

The tanning process can make leather more supple or more rigid, depending on the chemicals and techniques applied.

Additional treatments, such as oils or waxes, further affect the leather’s pliability.

Leather temper ranges from soft and pliable to hard and rigid, which impacts its suitability for various products.

I select leather with the right balance of flexibility for each project. For example, I choose soft, pliable leather for gloves and apparel, while I prefer firmer leather for belts and saddles. The ability to tailor flexibility makes leather a versatile material in my work.

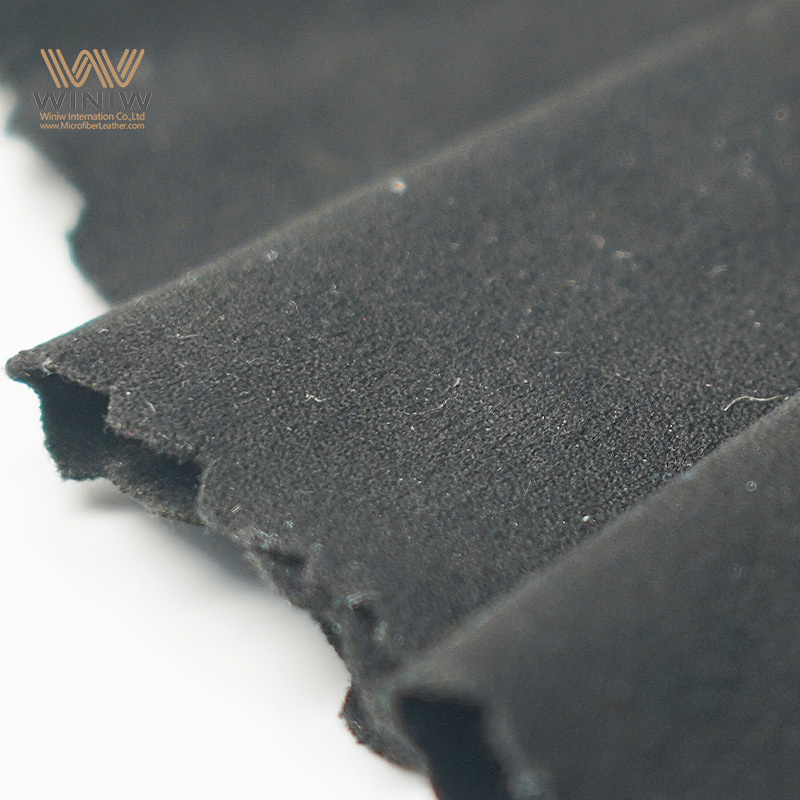

The aesthetics of leather play a major role in its appeal. I always look for visual indicators that signal high-quality leather. These include:

Natural imperfections, such as small blemishes or scars, which show the leather has not been overly processed.

Raw, unfinished edges that distinguish genuine leather from synthetic alternatives.

Unique grain patterns and visible pores, especially in full-grain leather, which make each piece one-of-a-kind.

I appreciate the aesthetics of leather because they combine authenticity with elegance. The natural grain and minor imperfections add character, while the rich color and sheen enhance the overall look. The aesthetics of leather improve with age, as the surface develops a patina that deepens its beauty.

Note: I always remind clients that the best leather showcases its natural features. Uniformity often signals lower quality or synthetic materials.

The properties of leather fabric—durability, flexibility, and appearance—set it apart from other materials. I rely on these qualities to deliver products that are not only functional but also visually striking.

When I evaluate leather fabric, comfort always plays a central role in my decision-making. I notice that leather offers a unique tactile experience. The surface feels smooth and cool to the touch, which adds a sense of luxury to any product. I often choose leather for seating and apparel because it adapts to body temperature, creating a pleasant sensation during use.

Leather’s natural breathability sets it apart from many synthetic materials. The porous structure allows air and moisture to pass through, which helps regulate temperature and prevents discomfort from overheating. I find this especially important in automotive interiors and furniture, where prolonged contact can lead to sweating or irritation with less breathable fabrics.

I have compared leather to other upholstery materials in consumer studies. The results consistently show that leather excels in comfort, especially in controlled environments. Here are some key findings:

Leather provides a luxurious tactile quality, which enhances comfort through superior strength and longevity.

Fabric upholstery, particularly synthetic fibers, offers versatility and ease of care, contributing to comfort in different climates.

Leather performs best in regulated environments, while treated fabric adapts well to diverse climatic conditions.

Leather resists physical tearing and abrasion, which increases comfort in high-stress situations.

Fabric balances durability and versatility, making it suitable for daily use and changing conditions.

In high humidity and heat, high-quality synthetic fabric may outperform leather, maintaining comfort.

I always consider these factors when recommending materials for clients. Leather’s ability to resist wear and maintain its shape means that cushions and seats stay supportive over time. I have seen leather furniture retain its comfort for years, even with heavy use. The material molds slightly to the user’s body, providing personalized support without losing structure.

Tip: I suggest using leather in spaces with climate control. The material feels cool in summer and warm in winter, but extreme humidity or heat can affect comfort. For outdoor or high-humidity areas, I sometimes recommend treated fabrics that handle moisture better.

I also appreciate how leather’s comfort improves with age. The surface softens and develops a patina, which adds to the tactile pleasure. Unlike many synthetic materials, leather does not become brittle or lose its supportive qualities quickly. I find that well-maintained leather continues to offer comfort long after installation.

When I select leather for apparel, I value its flexibility and ability to conform to movement. Jackets, gloves, and shoes made from leather provide both protection and comfort. The material stretches slightly, accommodating motion without restricting the wearer.

I see leather fabric as a staple in the fashion industry. Designers rely on its durability and luxurious appearance to create jackets, pants, skirts, and dresses. I often choose leather for its ability to hold shape while remaining flexible. This material adapts to both classic and modern styles. I notice that leather fabric resists wind and moisture, making it ideal for outerwear. Many brands use it for high-end handbags, belts, and shoes. The natural patina that develops over time adds character to each piece. I value how leather fabric elevates accessories, giving them a premium feel and long-lasting appeal.

When I select materials for furniture, I often turn to leather fabric for its blend of comfort and sophistication. I appreciate how it transforms sofas, chairs, and ottomans into statement pieces. The choice of leather type impacts both look and performance. I use the following table to compare the most common types of leather in furniture manufacturing:

|

Leather Type |

Characteristics |

Reasons for Preference |

|---|---|---|

|

Full-grain |

Highest quality, retains natural oils, resists damage |

Luxury feel, longevity, unique appearance |

|

Top-grain |

Thinned and buffed, uniform finish, easy to mold |

Good quality, easy to work with, pleasing finish |

|

Corrected-grain |

Buffed to remove imperfections, more affordable |

Cost-effective, decent appearance |

|

Split-grain |

Lower layers of hide, less durable |

Affordable, suitable for less-used furniture |

|

Nubuck |

Sanded for soft texture, similar to suede |

Soft feel, unique texture, used in high-end furniture |

|

Hair on hide |

Retains hair, unique appearance |

Distinctive look, used in rustic or eclectic styles |

|

Sheepskin |

Soft and plush, used for throws and cushions |

Luxurious feel, warmth, comfort |

I prefer full-grain leather for its unmatched durability and natural beauty. Top-grain leather offers a smooth finish and works well for modern designs. For budget projects, I sometimes use corrected-grain or split-grain leather fabric. Nubuck and sheepskin add softness and warmth to accent pieces. I always match the type of leather fabric to the intended use and desired aesthetic.

Tip: I recommend regular conditioning to maintain the softness and luster of leather furniture.

In the automotive industry, I see leather fabric as a symbol of luxury and comfort. Car manufacturers use it for seats, steering wheels, and trim. I choose leather for its premium look and feel. It adapts to temperature changes, providing comfort in both hot and cold weather. I value its durability, as it resists wear and tear better than most synthetic materials. The versatility of leather fabric allows for a wide range of colors and designs, which helps me create custom interiors.

Leather fabric gives vehicles a luxurious appearance.

It offers superior comfort by adapting to temperature changes.

The material resists wear, making it ideal for high-traffic areas.

Zeology leather provides excellent lightfastness, preventing fading from sunlight.

Sustainable options like compostable leather reduce environmental impact.

I find that the uses and applications of leather fabric in automotive interiors continue to expand as technology and sustainability improve. The unique qualities of leather fabric make it a top choice for drivers who value both style and performance.

I often recommend leather accessories to clients who want both style and practicality. Leather stands out in the world of accessories because it combines durability with a timeless look. I see strong demand for leather goods such as wallets, belts, watch straps, and cardholders. These items hold up well to daily use and develop character over time.

When I analyze the market, I notice several trends shaping the popularity of leather accessories:

Consumers want products that last. Many buyers choose leather for its longevity and resistance to wear.

Luxury brands lead the way with handmade, high-end leather accessories. These appeal to clients who value craftsmanship and exclusivity.

Sustainability drives demand for plant-based and recycled leather alternatives. Eco-conscious buyers look for accessories that minimize environmental impact.

Minimalism and functionality are top priorities. I see more people choosing slim wallets, compact bags, and multi-use items.

Technology integration is on the rise. Smart features in leather goods, such as RFID-blocking wallets or tech-friendly watch bands, attract tech-savvy consumers.

E-commerce platforms make it easier for buyers to find unique leather accessories from around the world.

I also observe a growing interest in small leather goods among younger consumers. Items like cardholders and minimalist wallets fit modern lifestyles. Exotic leathers, such as ostrich, remain popular with luxury shoppers who want something distinctive.

Tip: I always advise clients to invest in quality leather accessories. Well-made pieces not only last longer but also improve in appearance with age.

Leather fabric extends far beyond fashion and traditional accessories. I work with clients in many industries who seek innovative applications for this versatile material. In the tech sector, I see leather used for premium cases and covers for devices like smartphones and laptops. Brands such as Apple and Nomad offer leather cases and watch bands that combine protection with elegance.

Home décor designers use leather for wall coverings, lighting fixtures, and accent pieces. I have installed leather panels in offices and living rooms to add warmth and sophistication. Restoration Hardware and Tom Dixon create unique interior elements using leather, elevating the overall aesthetic.

Wearable technology also benefits from leather’s qualities. Companies like Montblanc and Fitbit use leather in smartwatches and fitness trackers. These products merge classic style with modern functionality.

Sustainability remains a key focus. I see companies developing leather-like materials from organic by-products. Brands such as VEERAH promote eco-friendly practices by offering plant-based alternatives that mimic the look and feel of traditional leather.

Here are some less common uses of leather fabric:

High-end tech accessories (phone and laptop cases)

Smartwatch and fitness tracker bands

Wall coverings and lighting in interior design

Sustainable, plant-based leather alternatives

I believe leather’s adaptability ensures its continued relevance across industries. Whether in technology, home décor, or sustainable innovation, leather fabric continues to inspire new possibilities.

I always start my leather care routine with proper cleaning. Clean leather not only looks better but also lasts longer. I follow a step-by-step approach to ensure I do not damage the material:

I dust the surface with a soft, dry cloth to remove loose dirt.

For light dirt or spills, I use a mild soap solution. I dampen a clean cloth with the solution and gently wipe the leather. I avoid soaking the material.

When I encounter tough stains, I turn to professional leather cleaners. These products preserve the integrity of the leather and remove stubborn marks without causing harm.

Occasionally, I use a mixture of vinegar and natural oils for a deeper clean. I always test this method on a hidden spot first to ensure it does not discolor the leather.

After cleaning, I apply a UV-protective spray. This step helps prevent fading and damage from sunlight, especially for items exposed to direct light.

Tip: I never use harsh chemicals or abrasive tools on leather. Gentle cleaning preserves both the look and feel of the fabric.

Conditioning keeps leather soft, supple, and resistant to cracks. I consider this step essential, especially for items that see frequent use or exposure to heat. I rely on several effective products:

I use lanolin-based conditioners for deep nourishment.

Leather creams and lotions work well for regular maintenance.

When leather feels dry or looks dull, I condition it more often—sometimes every three to four months for items exposed to sunlight or heat.

I recommend conditioning every six to twelve months for most leather goods. If I notice the leather losing its luster or flexibility, I do not wait for the scheduled interval. I apply conditioner as soon as needed. This proactive approach prevents premature aging and keeps the material looking its best.

Note: I always let the conditioner absorb fully before using or storing the item. Excess product can attract dust and cause buildup.

Proper storage protects leather from damage and extends its lifespan. I follow these best practices for storing leather items:

I clean and condition leather before putting it away. This step prevents stains and odors from setting in.

I inspect each item for damage. Addressing issues early stops them from getting worse during storage.

I avoid plastic bags. Instead, I use breathable cotton or canvas covers to allow air circulation.

For garments, I hang them on wide, padded hangers to maintain their shape.

I store leather in dark areas to shield it from sunlight, which can cause fading.

I check regularly for moisture. If I find any, I address it immediately to prevent mold growth.

When stacking or folding, I use acid-free tissue paper to protect the surface.

Tip: I never overcrowd storage spaces. Leather needs room to breathe, which helps prevent creasing and deformation.

When I care for leather fabric, I always pay close attention to the details. Over the years, I have noticed that many people make the same mistakes, which can shorten the lifespan of their leather goods. I want to share the most common pitfalls I see and offer advice on how to avoid them.

Using inappropriate cleaning products

I often see people reach for household cleaners or harsh chemicals when cleaning leather. This approach can strip away natural oils and damage the surface. Each type of leather requires specific care. For example, suede and nubuck need special brushes and dry-cleaning methods. Full-grain leather benefits from conditioning creams. I always check the manufacturer’s recommendations before applying any product.

Neglecting conditioning

Many people forget to condition their leather items. I have seen beautiful leather crack and dry out because it lacked moisture. Regular conditioning keeps leather supple and prevents it from becoming brittle. I set reminders to condition my leather goods every few months, especially if they see frequent use.

Over-conditioning

Some believe that more conditioner means better results. I have learned that too much conditioner can leave a sticky residue and change the texture of the leather. I apply a thin, even layer and let it absorb fully before using or storing the item. Moderation is key.

Exposure to moisture

Leather does not like water. I have seen water stains and warping on leather that was left in damp environments or exposed to rain. I always dry wet leather slowly at room temperature and never use direct heat. I also use protective sprays to add a layer of water resistance.

Improper storage

Storing leather incorrectly can cause permanent damage. I avoid overstuffing bags, which can distort their shape and weaken seams. I empty unnecessary contents and store items in breathable covers. For jackets and garments, I use wide, padded hangers to help them keep their form.

Tip: I always recommend inspecting leather goods regularly. Early detection of issues like dryness, stains, or misshapen areas allows for quick intervention and prevents long-term damage.

I have found that avoiding these common mistakes makes a significant difference in the longevity and appearance of leather fabric. By choosing the right products, conditioning regularly but not excessively, protecting from moisture, and storing items properly, I ensure that my leather goods remain beautiful and functional for years.

When I assess the sustainability of leather fabric, I always start with its environmental footprint. The production of leather fabric requires significant resources and creates pollution at multiple stages. I have seen the following impacts in my work:

The leather tanning industry can use up to 17,000 liters of fresh water to produce just one square meter of leather fabric.

Livestock farming, which supplies hides for leather, accounts for about 14.5% of total global greenhouse gas emissions. Cattle farming is the largest contributor.

Producing one square meter of finished leather results in 22.48 kg of CO₂ equivalent emissions. Most of these emissions come from farming and slaughtering.

Leather production generates large amounts of waste. This includes solid waste like trimmings and shavings, as well as liquid waste that contains toxic chemicals.

Note: I always consider these factors when recommending leather fabric for a project. The environmental impact of traditional leather makes it important to explore more sustainable options.

I have noticed a growing demand for alternatives to traditional leather fabric. Many of my clients ask about eco-friendly materials that offer similar qualities. Several innovative options have emerged in recent years. Piñatex, made from pineapple leaf fibers, stands out because it uses agricultural waste and is biodegradable. Mushroom leather, produced from mycelium, offers a renewable and soft material that can be grown using agricultural byproducts. Cactus leather requires very little water and grows in a carbon-neutral way. Apple leather and cork leather also use waste from the food and forestry industries, making them more sustainable.

Here are some of the most widely used alternatives:

Piñatex: Made from pineapple leaf waste, biodegradable, and less toxic than traditional leather fabric.

Mushroom Leather: Grown from mycelium, biodegradable, and has a small environmental footprint.

Cactus Leather: Sourced from nopal cactus, requires minimal water, and is mostly biodegradable.

Apple Leather: Created from apple waste, partially biodegradable, and uses food industry byproducts.

Cork Leather: Harvested from cork oak trees without harming them, renewable, and biodegradable.

I have tested many of these materials in my projects. While they do not always match the durability of traditional leather fabric, they offer a promising path toward more sustainable design.

When I choose leather fabric for my clients, I always look for suppliers who follow responsible sourcing practices. Certifications and standards help me verify that the leather or its alternatives meet strict environmental and safety criteria. I rely on the following certifications to guide my decisions:

|

Certification/Standard |

Focus Areas |

Benefits |

|---|---|---|

|

ISO 3376 |

Tensile strength |

Quality assurance |

|

OEKO-TEX® Leather Standard |

Chemical safety |

Safety for human contact |

|

Global Organic Textile Standard |

Leather alternatives |

Organic certification |

|

REACH Compliance |

Chemical regulations |

Compliance with EU standards |

|

Bluesign® |

Sustainable manufacturing |

Environmental responsibility |

|

Cradle to Cradle Certified™ |

Material health |

Circular economy design |

Tip: I always recommend checking for these certifications when purchasing leather fabric. They provide assurance that the material meets high standards for quality, safety, and sustainability.

By considering environmental impact, exploring alternatives, and choosing responsibly sourced leather fabric, I help my clients make informed and sustainable choices.

I see leather fabric as a unique material that combines durability, flexibility, and timeless appeal. By understanding how leather is made, its different types, and its core properties, I can make better choices for my projects. I always consider the uses, care routines, and sustainability factors before selecting leather. I encourage readers to weigh both practical needs and environmental impact when choosing leather products for any application.

I always use a soft, damp cloth and mild soap for routine cleaning. I avoid harsh chemicals. For tough stains, I trust professional leather cleaners. I test any new product on a hidden area first.

I check the texture and smell. Real leather has a unique scent and natural imperfections. Synthetic leather feels more uniform and often lacks the rich aroma. I sometimes look for a label or ask the supplier for details.

Yes, I notice that leather fabric stretches slightly with use, especially in shoes and upholstery. I always recommend buying a snug fit. Overstretching can cause permanent deformation, so I avoid excessive force.

Minor scratches often fade with gentle rubbing or conditioning. For deeper scuffs, I use specialized leather repair kits. I follow the instructions carefully to restore the surface without causing further damage.

Leather resists water to some extent, but it is not fully waterproof. I apply a water-repellent spray for extra protection. Prolonged exposure to moisture can damage leather, so I dry it promptly if it gets wet.

I recommend Piñatex, mushroom leather, and cactus leather. These materials use renewable resources and have a lower environmental impact. I always check for certifications to ensure the alternative meets my sustainability standards.

I condition leather every six to twelve months. For items exposed to sunlight or frequent use, I increase the frequency. Regular conditioning keeps leather soft, prevents cracking, and extends its lifespan.

Leather develops a patina from exposure to light, air, and handling. I appreciate this natural aging process. The patina adds character and depth, making each leather item unique over time.