-

Tel : +8618150976625

-

Email : Hello@MicrofiberLeather.com

Tel : +8618150976625

Email : Hello@MicrofiberLeather.com

Polyurethane, or PU material, appears in countless everyday household items due to its unique blend of versatility, durability, and comfort. People encounter PU material in sofas, mattresses, shoes, and even refrigerators, where it enhances both human comfort and product longevity. The following table highlights key benefits found in many everyday items:

|

Benefit/Application |

Description |

|---|---|

|

Versatility |

Adaptable for construction, apparel, and more. |

|

Durability |

Ensures strength and long life in daily products. |

|

Energy Efficiency |

Adds thermal insulation in appliances. |

|

Comfort |

Improves support in carpets and seating. |

|

Aesthetic Appeal |

Enhances surface appearance and upkeep. |

|

Cost-Effectiveness |

Offers affordability and long-term value. |

Polyurethane (PU) material enhances comfort and durability in everyday items like furniture and bedding.

High-density PU foam provides better support and lasts longer, making it ideal for sofas and mattresses.

PU insulation panels can reduce energy consumption by up to 30%, leading to lower heating and cooling costs.

Footwear made with PU offers excellent cushioning and lightweight properties, improving comfort during daily activities.

PU leather serves as a cruelty-free alternative to genuine leather, providing style and easy maintenance.

Polyurethane coatings protect surfaces from scratches and moisture, extending the life of furniture and appliances.

Regular inspection of PU seals and gaskets can prevent leaks and extend the lifespan of appliances and vehicles.

Innovations in PU materials aim to address environmental concerns, promoting safer and more sustainable options.

Polyurethane plays a vital role in the construction of modern furniture. Manufacturers rely on this material to create sofas, chairs, and office furniture that deliver both comfort and durability. Polyurethane foam, in particular, stands out as a core component in many everyday items found in homes and offices.

Furniture and bedding often feature polyurethane foam as the main cushioning layer. This material adapts to the shape of the body, providing a high level of human comfort. People notice the difference when they sit on a sofa or chair that uses this foam. The seat feels soft yet supportive, making it ideal for long periods of sitting.

Polyurethane foam offers excellent support for users of all ages and body types. The foam distributes weight evenly, which helps reduce pressure points and prevents discomfort during extended use. In office furniture, this support can improve posture and reduce fatigue. Sofas and chairs with high-density polyurethane foam maintain their shape and firmness over time, ensuring that users receive consistent support.

Tip: When shopping for new furniture, check the foam density. Higher-density polyurethane foam provides better support and lasts longer.

Durability remains a key reason why manufacturers choose polyurethane for furniture. The lifespan of polyurethane foam cushions depends on their density. For example, cushions with a density of 1.8 typically last about five years for a person weighing 180 pounds. However, heavier users may notice a shorter lifespan. In contrast, cushions with a density of 2.5 can last up to 15 years for the same user, showing a clear advantage in longevity. While Spring Down and Spring Fiber cushions may outlast lower-density foam, high-density polyurethane foam still offers impressive durability for most everyday items.

|

Cushion Type |

Typical Lifespan (180 lbs user) |

Notes |

|---|---|---|

|

1.8 Density PU Foam |

~5 years |

Shorter lifespan for heavier users |

|

2.5 Density PU Foam |

Up to 15 years |

Greater durability |

|

Spring Down/Fiber |

15+ years |

Minimal firmness loss |

Polyurethane also resists sagging and deformation, which helps furniture retain its original appearance. This resistance to wear and tear makes polyurethane a preferred choice for both residential and commercial furniture.

Furniture made with PU material combines comfort, support, and durability. These qualities ensure that sofas, chairs, and office furniture remain reliable and attractive parts of daily life.

Modern bedding relies heavily on polyurethane to deliver comfort, support, and health benefits. Many manufacturers use this material in both mattresses and pillows, making it a staple in furniture and bedding. Polyurethane stands out for its adaptability, which allows it to meet the needs of a wide range of sleepers.

Polyurethane has revolutionized the mattress industry. Memory foam technology, a specialized form of polyurethane, adapts to the body’s contours. This innovation has changed how people experience sleep.

A soft mattress made with memory foam provides targeted pressure relief. The foam molds to the sleeper’s body, distributing weight evenly. This process reduces stress on joints and minimizes discomfort. People who suffer from back pain or joint issues often find significant improvement when they switch to a mattress containing polyurethane. The material’s ability to cushion pressure points helps prevent tossing and turning during the night.

Note: Memory foam mattresses can help athletes and active individuals recover faster by reducing pressure on muscles and joints.

Polyurethane mattresses offer hypoallergenic properties. The dense structure of the material resists dust mites and other common allergens. Sensitive users benefit from this feature, as it helps create a cleaner sleeping environment. Many everyday items in the bedroom, such as mattress toppers and protectors, also use polyurethane for this reason. People with allergies or asthma often choose these products to improve their sleep quality.

Pillows made with polyurethane provide a unique blend of comfort and support. Manufacturers design these pillows to complement mattresses, ensuring a restful night’s sleep.

Polyurethane pillows deliver exceptional softness without sacrificing support. The material cradles the head and neck, maintaining alignment throughout the night. This balance of softness and structure helps reduce neck pain and stiffness. Many users notice that their sleep improves when they switch to pillows made from this advanced material.

Polyurethane pillows retain their shape longer than traditional fiber-filled options.

The foam resists flattening, which means consistent comfort over time.

People seeking a comfortable and healthy sleep environment often turn to polyurethane-based bedding. The combination of pressure relief, hypoallergenic qualities, and lasting softness makes this material a top choice for modern bedrooms.

Polyurethane stands as a leading choice for insulation in both residential and commercial settings. Builders and manufacturers select this material for its outstanding thermal efficiency and moisture resistance. PU material helps maintain comfortable indoor temperatures and protects structures and appliances from environmental stress.

Polyurethane insulation panels have transformed modern construction. These panels offer superior performance compared to traditional insulation materials.

PU sandwich panels deliver significant energy savings. Buildings equipped with these panels often experience lower heating and cooling costs. The advanced thermal insulation properties of polyurethane reduce energy consumption by up to 30% when compared to older insulation methods. Homeowners and facility managers notice these savings over time, making polyurethane panels a cost-effective solution.

PU sandwich panels can reduce energy consumption by up to 30% compared to traditional insulation materials.

They lead to noticeable energy savings over time due to superior thermal insulation properties.

Buildings with PU panels often experience lower heating and cooling costs.

Polyurethane panels also serve as an effective moisture barrier. The closed-cell structure of the material blocks water vapor and prevents condensation within walls. This feature protects buildings from mold growth and structural damage. Contractors rely on polyurethane insulation to maintain dry, healthy environments in homes and offices.

|

Feature |

Benefit |

|---|---|

|

Thermal Insulation |

Lower energy bills |

|

Moisture Barrier |

Prevents mold and damage |

|

Longevity |

Extends building lifespan |

Manufacturers use polyurethane extensively in home appliances, especially refrigerators and freezers. This application ensures optimal performance and energy efficiency.

Polyurethane foam fills the space between the outer metal casing and the inner liner of refrigerators. This insulation type creates a thermal barrier that keeps cold air inside and blocks heat from entering. As a result, refrigerators maintain consistent temperatures and operate efficiently. Polyurethane insulation helps reduce electricity usage and extends the lifespan of the appliance.

Freezers also benefit from polyurethane insulation. The foam provides reliable thermal isolation, preserving food quality and safety. Polyurethane’s moisture resistance prevents ice buildup and protects internal components. Appliance manufacturers favor this material for its durability and ability to maintain low temperatures.

Polyurethane foam dominates the market for insulation in refrigerators and freezers. Its placement between the metal shell and polyethylene liner highlights its importance in energy conservation. Consumers enjoy lower utility bills and longer-lasting appliances due to the superior performance of polyurethane insulation.

Tip: When purchasing new appliances, check for polyurethane insulation. This feature often signals better energy efficiency and longer service life.

Polyurethane has transformed the design and performance of modern footwear. Manufacturers use this material in a wide range of shoes, including athletic footwear, boots, and even high heels. Polyurethane offers a unique combination of comfort, lightweight construction, and reliable support, making it a preferred choice for both casual and performance-oriented shoes.

Sneakers often feature polyurethane in their midsoles and outsoles. This material helps brands deliver shoes that feel comfortable and perform well during daily activities or sports.

Polyurethane provides excellent shock absorption in sneakers. The midsole, made from this material, absorbs impact forces when the foot strikes the ground. This feature reduces stress on joints and muscles, which helps athletes and everyday users stay comfortable during long periods of walking or running. Many people notice less fatigue in their legs and feet after wearing sneakers with polyurethane midsoles.

Tip: Look for sneakers with polyurethane midsoles if you need extra cushioning for high-impact activities.

Polyurethane stands out for its lightweight properties. Shoes made with this material feel less heavy, which allows users to move more freely and quickly. Lightweight sneakers help improve agility and speed, especially in sports settings. The reduced weight also means less strain on the legs, making these shoes ideal for people who spend many hours on their feet.

Boots require materials that can withstand tough conditions. Polyurethane plays a significant role in providing comfort and support, but its durability varies depending on the environment.

Polyurethane soles in boots offer good resistance to wear and tear in everyday situations. They maintain their shape and cushioning over time, which ensures consistent comfort. However, when compared to rubber soles, polyurethane soles have a shorter lifespan, especially in harsh environments with sharp objects or rough surfaces. Rubber soles can last for several years and provide better abrasion resistance and grip on wet surfaces. In contrast, polyurethane soles typically last between one and three years. Despite this, many users prefer polyurethane for its comfort and lightweight feel.

Rubber soles generally outlast polyurethane soles in demanding conditions.

Polyurethane soles provide adequate durability for regular, everyday use.

Rubber offers superior grip and abrasion resistance, especially on wet or rough terrain.

Polyurethane continues to shape the future of footwear by balancing comfort, shock absorption, and lightweight design. Whether in athletic footwear, boots, or casual shoes, this material helps manufacturers meet the needs of diverse users.

Automotive manufacturers rely on polyurethane to enhance both the performance and comfort of vehicles. This versatile material appears in critical components such as suspension bushings and car interiors, where it delivers notable improvements in safety, durability, and passenger experience.

Polyurethane bushings have become a preferred choice for vehicle suspension systems. Engineers select this material for its ability to withstand heavy loads and resist wear over time.

Polyurethane bushings outperform traditional rubber bushings in several ways. They maintain their shape under pressure, which helps stabilize the suspension and improve handling. Drivers experience more precise steering and better control, especially during sharp turns or sudden maneuvers. The material’s resistance to deformation ensures that suspension components last longer, reducing the need for frequent replacements.

|

Material |

Handling Precision |

Lifespan |

Maintenance |

|---|---|---|---|

|

Polyurethane |

High |

Extended |

Low |

|

Rubber |

Moderate |

Shorter |

Higher |

Vehicle owners often notice a quieter ride when manufacturers use polyurethane in suspension and muffler systems. This material absorbs vibrations and dampens road noise more effectively than rubber. Cast polyurethane in muffler systems further reduces unwanted sounds, contributing to a peaceful cabin environment. A quieter interior allows passengers to concentrate better and react quickly to driving conditions, which enhances overall safety.

Polyurethane foams provide effective sound insulation in car interiors.

Cast polyurethane in muffler systems improves noise reduction and durability.

Reduced road noise leads to a safer and more comfortable driving experience.

Polyurethane plays a vital role in creating comfortable and durable car interiors. Designers use this material in seats, dashboards, and insulation panels to improve passenger satisfaction.

Automotive seats often feature polyurethane foam as the primary cushioning layer. This foam adapts to the shape of the occupant, providing support and comfort during long journeys. The material resists sagging and maintains its structure, ensuring that seats remain comfortable and attractive over time. Passengers benefit from reduced fatigue and better posture, which makes travel more enjoyable.

Tip: Vehicles with polyurethane seat cushions offer superior comfort for daily commutes and long road trips.

Manufacturers use polyurethane in dashboards to achieve a balance between durability and aesthetics. The material withstands temperature changes and exposure to sunlight without cracking or fading. Polyurethane dashboards retain their appearance and structural integrity, even after years of use. This reliability helps maintain the value and appeal of the vehicle.

Polyurethane continues to shape the future of automotive design. Its presence in suspension systems and interiors demonstrates a commitment to comfort, safety, and long-lasting performance.

Polyurethane coatings play a crucial role in protecting and enhancing surfaces in homes, vehicles, and industrial settings. These coatings offer a blend of durability, flexibility, and resistance to environmental stressors. Manufacturers and professionals choose polyurethane for its ability to deliver long-lasting results on a variety of materials.

Protective paints made with polyurethane shield surfaces from scratches, moisture, and chemicals. Homeowners often select these paints for high-traffic areas, such as kitchen cabinets and floors. Industrial facilities rely on them to guard machinery and metal structures against corrosion. Polyurethane forms a tough barrier that resists daily wear and tear. This property helps maintain the appearance and integrity of surfaces over time.

Polyurethane-based paints excel in environments where durability is essential.

These paints reduce maintenance costs by minimizing the need for frequent touch-ups.

Polyurethane paints adapt to many surfaces, including wood, metal, and concrete. Painters appreciate the smooth finish and wide range of available colors. The coatings can be applied indoors or outdoors, making them suitable for furniture, fences, and even boats. Solvent-based polyurethane coatings are projected to account for 46.3% of the polyurethane coating market in 2025. This statistic highlights the widespread trust in their performance and adaptability.

Note: Polyurethane paints often dry faster than traditional options, allowing for quicker project completion.

Polyurethane finishes extend the life of wood and metal surfaces. Furniture makers use these finishes to protect tables, chairs, and cabinets from scratches and stains. The clear, glossy layer enhances the natural beauty of wood while providing a strong shield. Metalworkers apply polyurethane finishes to prevent rust and fading. These finishes resist chemicals and UV rays, which helps surfaces retain their appearance for years.

|

Feature |

Benefit |

|---|---|

|

Scratch Resistance |

Maintains surface quality |

|

Chemical Resistance |

Prevents staining and damage |

|

UV Protection |

Reduces fading and discoloration |

Polyurethane coatings combine protection, versatility, and longevity. They help preserve the value and appearance of everyday items, from household furniture to industrial equipment.

Seals and gaskets made from polyurethane play a critical role in modern plumbing, automotive, and household appliances. Engineers and manufacturers choose PU material for these components because it offers a unique combination of reliability, flexibility, and long-term performance. These qualities help protect vital systems from leaks and environmental damage.

Polyurethane seals create airtight barriers in many essential systems. In plumbing, these seals prevent air and gas leaks that could compromise water pressure or system safety. Automotive engineers rely on PU gaskets to maintain engine integrity and reduce vibration. The material’s resilience ensures that seals remain effective even after repeated cycles of compression and expansion.

Leak prevention stands as a top priority in both residential and industrial applications. PU seals and gaskets deliver superior performance compared to traditional rubber alternatives. They resist wear and chemical degradation, which often cause rubber to become brittle and fail over time. Urethane seals protect components in vehicle engines and exhaust systems, reducing the risk of leaks that can lead to costly repairs or hazardous conditions. In plumbing, PU gaskets maintain system pressure and prevent water or gas from escaping, ensuring smooth operation.

Tip: Regular inspection of seals and gaskets in appliances and vehicles helps prevent unexpected leaks and extends equipment lifespan.

Key Advantages of PU Seals in Automotive and Plumbing:

Durable and flexible, outperforming many traditional materials.

Reduce vibration and protect sensitive components.

Maintain system pressure for optimal performance.

Offer greater resistance to chemicals and wear.

Polyurethane gaskets also provide watertight protection in a variety of settings. Appliance manufacturers use PU gaskets in washing machines, dishwashers, and refrigerators to prevent water ingress and protect electrical components. In the automotive industry, these gaskets shield critical systems from moisture and contaminants.

Flexibility defines the effectiveness of PU gaskets. The material adapts to surface irregularities, creating a tight seal even under fluctuating pressures and temperatures. This adaptability ensures reliable performance in high-pressure environments, such as hydraulic systems or engine compartments. PU gaskets maintain their sealing properties across a wide temperature range, avoiding excessive hardening or softening that can compromise function. Their outstanding chemical resistance allows them to withstand exposure to aggressive substances without degrading.

|

Feature |

Benefit |

|---|---|

|

Flexibility |

Adapts to uneven surfaces |

|

Thermal Stability |

Performs in extreme temperatures |

|

Chemical Resistance |

Withstands harsh substances |

|

Resilience |

Maintains seal under pressure |

Polyurethane’s unique properties make it the preferred choice for seals and gaskets in demanding applications. Its reliability and flexibility help ensure the safety and efficiency of plumbing systems, vehicles, and household appliances. As technology advances, PU material continues to set the standard for leak prevention and watertight protection.

Medical technology relies on advanced materials to ensure patient safety and device performance. Polyurethane stands out as a preferred choice for many medical devices due to its unique combination of strength, flexibility, and biocompatibility. Hospitals and clinics use this material in a wide range of products, including catheters, tubing, wound dressings, and implantable devices.

Medical devices must withstand repeated use and exposure to bodily fluids. Polyurethane delivers the durability required for these demanding environments. Manufacturers select this material for its resistance to tearing, abrasion, and chemical degradation. Catheters and tubing made from polyurethane maintain their integrity during insertion and removal, reducing the risk of device failure. This strength ensures that devices perform reliably throughout their intended lifespan.

Flexibility remains a critical property for devices that interact with the human body. Polyurethane adapts to movement and conforms to anatomical structures. Catheters and intravenous lines benefit from this flexibility, as they can navigate blood vessels and soft tissues without causing trauma. Patients experience greater comfort during procedures, and clinicians can position devices more accurately. The material’s ability to bend and stretch without breaking supports a wide range of medical applications.

Patient safety drives innovation in medical device materials. Polyurethane offers several features that help protect patients from infection and adverse reactions. Its smooth surface resists bacterial adhesion, which lowers the risk of infection during use. Medical-grade polyurethanes, such as Pellethane and Tecoflex, have been engineered specifically for healthcare settings. These materials provide a reliable barrier against microbes and maintain their properties under sterilization.

Biocompatibility defines how well a material interacts with living tissue. Polyurethane has earned a strong reputation in this area. Researchers have improved its compatibility with blood, leading to better cell growth and fewer bacterial infections. Hospitals use polyurethane in cardiovascular devices, including central venous catheters and blood lines for dialysis. The material’s biostability ensures that it does not break down or release harmful substances inside the body. Medical professionals trust polyurethane for its proven track record in patient care.

Polyurethane is widely used in catheters, tubing, and implantable devices.

Medical-grade polyurethanes offer microbial barrier properties and long-term stability.

Research has demonstrated improved cell proliferation and reduced infection rates.

Polyurethane’s combination of strength, flexibility, and safety makes it an essential material in modern medical devices. Its adaptability supports innovation and helps improve patient outcomes across a variety of healthcare applications.

Carpet underlay plays a crucial role in residential and commercial flooring systems. Polyurethane (PU) foam underlay has become the preferred choice for many flooring professionals. This material offers a unique combination of comfort, durability, and protection that enhances the performance and lifespan of carpets.

PU foam underlay transforms the feel of any carpeted floor. Homeowners and building managers notice immediate improvements when they install this material beneath their carpets. The foam creates a soft, cushioned surface that feels pleasant underfoot. People who spend long hours standing or walking indoors appreciate the difference. The enhanced comfort provided by PU foam underlay makes it a popular option for bedrooms, living rooms, and office spaces.

Cushioning remains one of the most significant advantages of PU foam underlay. The material absorbs impact from footsteps and reduces strain on joints. Children, seniors, and anyone with sensitive feet benefit from the gentle support. The foam adapts to pressure, which helps maintain a consistent surface feel across the entire floor. This feature also protects the carpet fibers from crushing, extending the carpet’s appearance and usability.

Underlayment enhances comfort by making floors more pleasant to walk on.

It reduces noise from footsteps and other impacts, contributing to a quieter environment.

High-density materials in underlayment provide effective barriers against both airborne and impact sounds.

Durability defines the long-term value of PU foam underlay. The material resists wear and maintains its structure even after years of heavy use. Unlike some traditional underlays, PU foam does not break down or lose its resilience quickly. This quality ensures that carpets retain their plush feel and appearance for a longer period.

PU foam underlay acts as a protective barrier between the carpet and the subfloor. It shields the flooring from moisture, dirt, and minor imperfections. This protection prevents premature wear and helps maintain the integrity of both the carpet and the underlying surface. The foam’s resistance to compression means that it continues to support the carpet, even in high-traffic areas.

Noise reduction stands out as another key benefit. PU foam underlay absorbs sound from footsteps, voices, and moving furniture. This feature creates a quieter, more peaceful environment in homes and offices. High-density PU foam blocks both airborne and impact sounds, making it ideal for multi-story buildings or shared living spaces.

Flooring professionals often recommend PU foam underlay for its superior performance. The material’s combination of comfort, cushioning, and protection sets it apart from other options. While PU foam is best known for its use in carpet underlay, it also appears in products such as footwear, where similar qualities are valued.

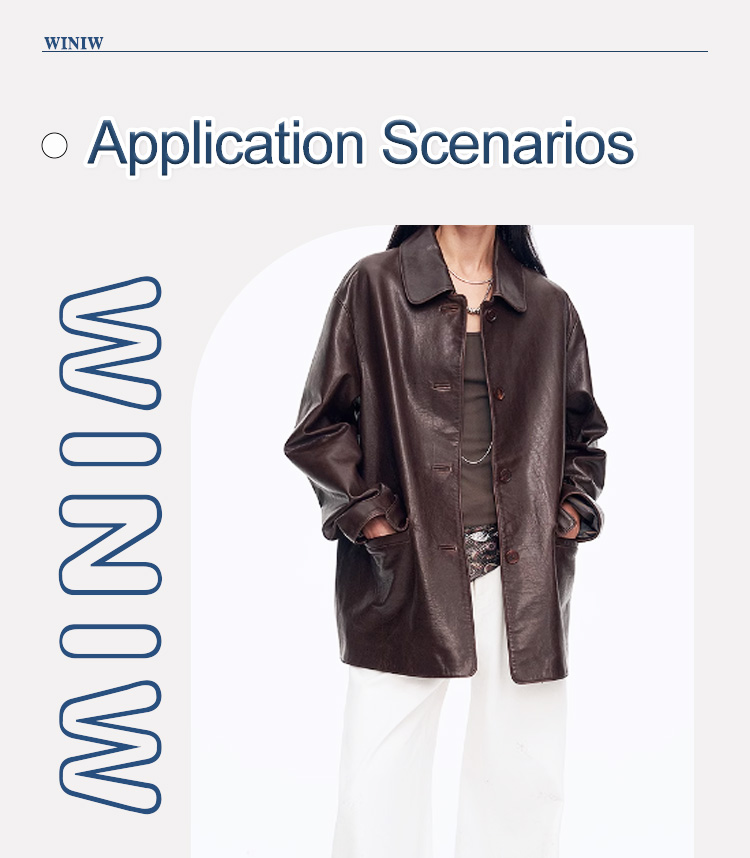

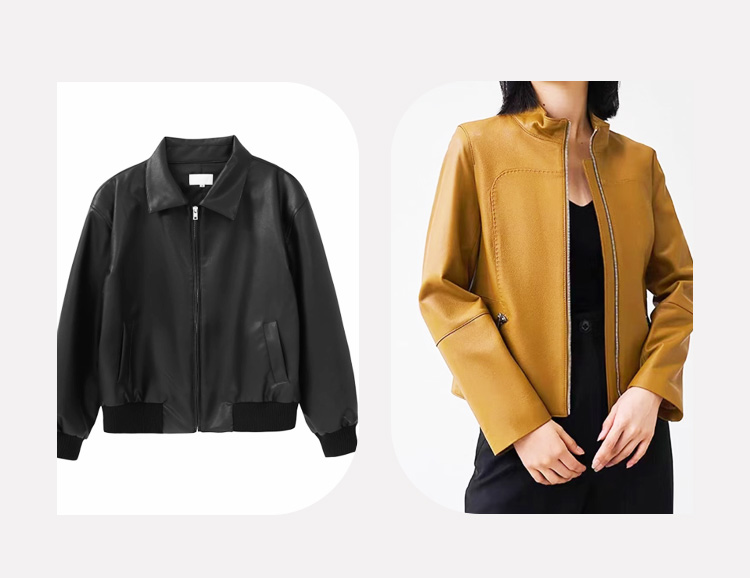

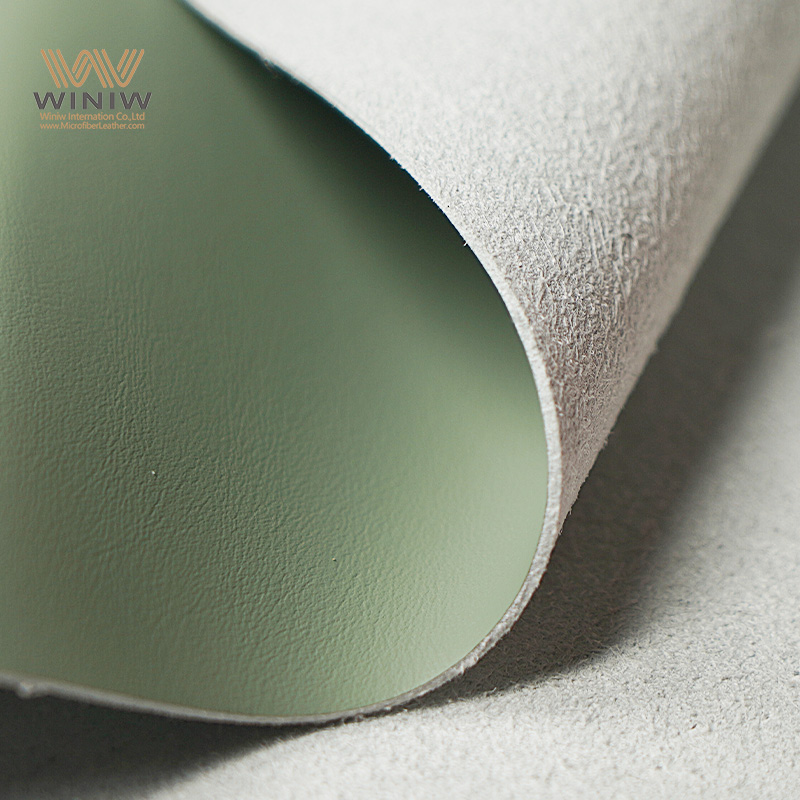

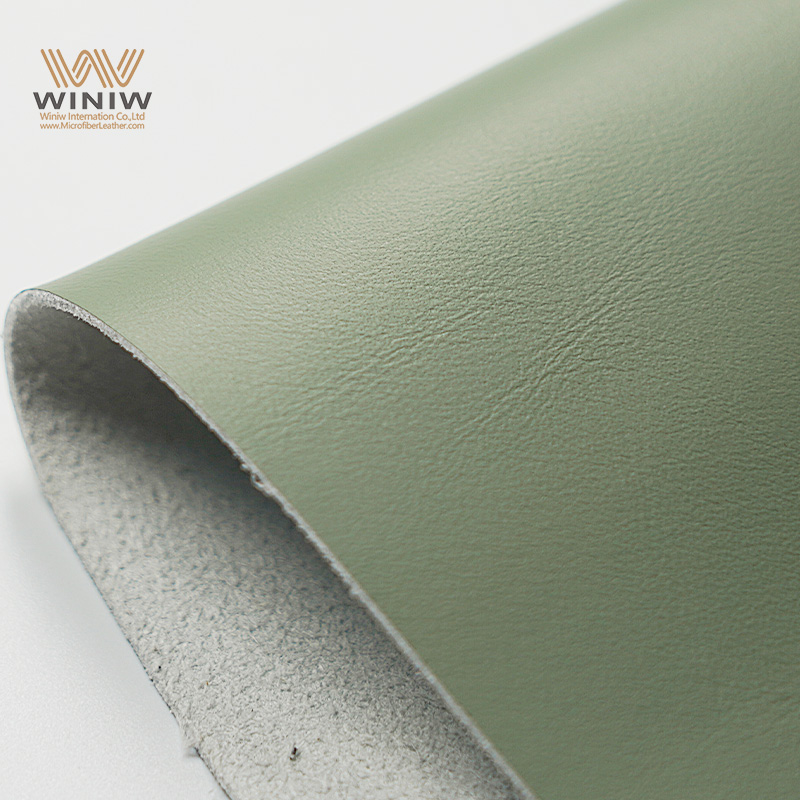

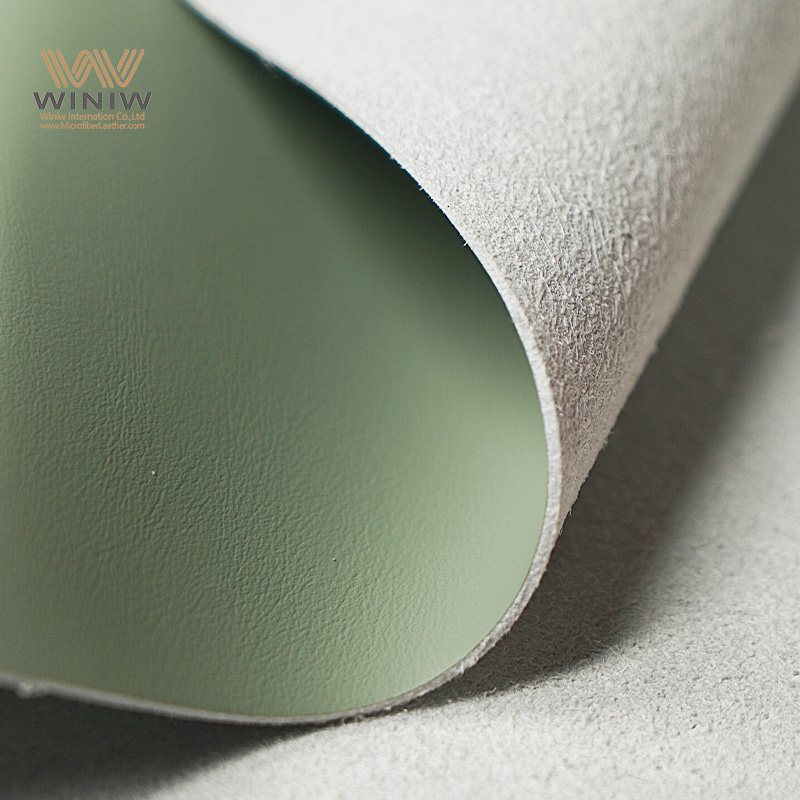

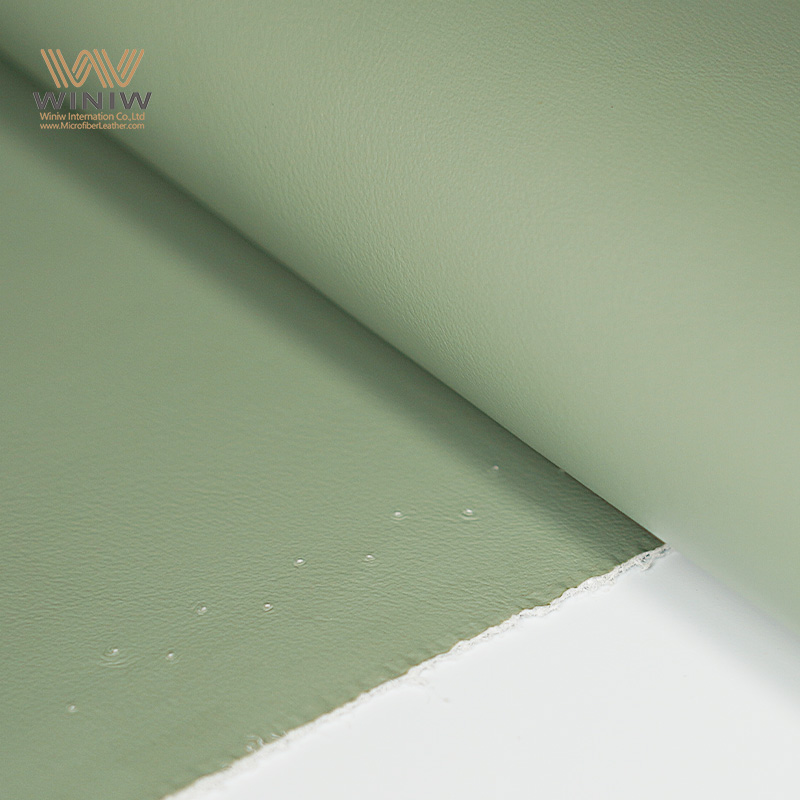

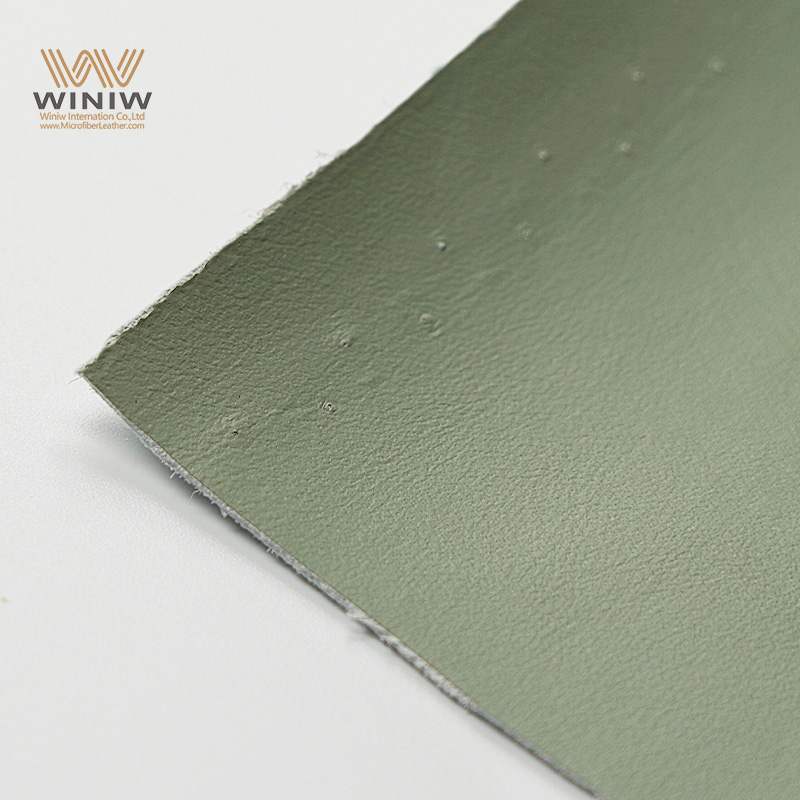

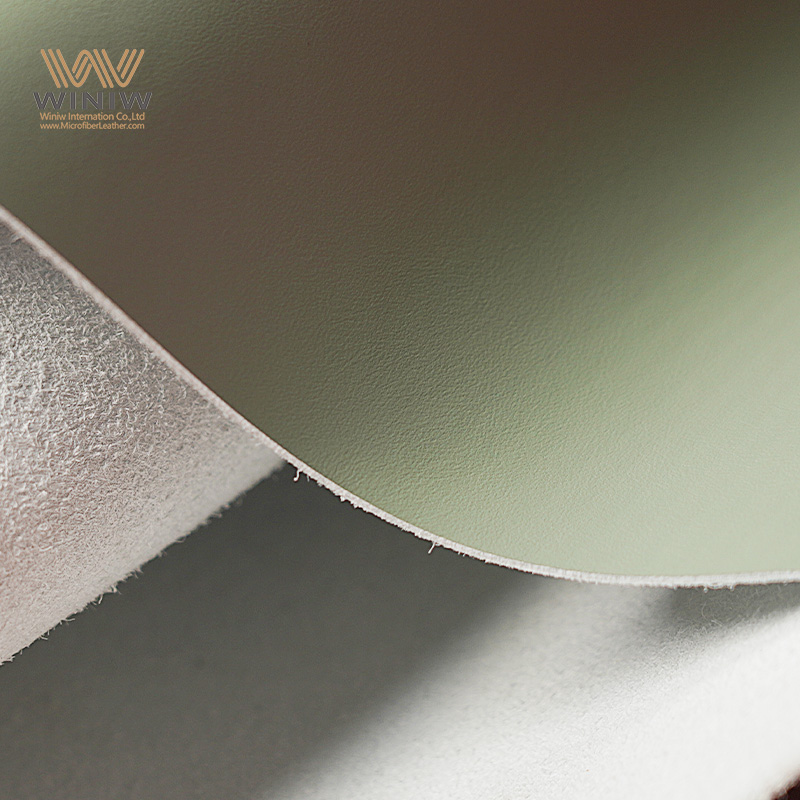

Polyurethane (PU) leather has become a staple in the modern fashion industry. Designers and manufacturers choose PU leather as a cruelty-free alternative to genuine leather. This synthetic material mimics the look and feel of real leather while eliminating the need for animal products. Consumers who value ethical choices often select PU leather for its vegan-friendly properties. The fashion world recognizes PU leather for its ability to deliver style, affordability, and easy care.

PU leather dominates many apparel categories. Its versatility allows designers to create fashionable items that appeal to a broad audience.

PU leather jackets offer a sleek, contemporary appearance. They provide a lightweight option that resists water and stains. Many brands use PU leather to produce jackets in a variety of colors and finishes. These jackets often feature modern cuts and detailing, making them popular among young adults and trendsetters. Unlike genuine leather, PU leather jackets require minimal maintenance. Owners can wipe them clean with a damp cloth, which simplifies care routines.

Fashion houses and retailers use PU leather to craft handbags, backpacks, and wallets. These accessories combine durability with a refined look. PU leather bags resist scratches and maintain their shape over time. The material’s flexibility enables designers to experiment with textures and patterns. Consumers appreciate the wide range of styles available at accessible price points. PU leather bags often weigh less than their genuine leather counterparts, adding to their everyday practicality.

Note: PU leather’s affordability stems from its efficient production process. Mass production lowers costs, allowing brands to offer stylish products without premium pricing.

PU leather extends beyond clothing and accessories. Furniture makers rely on this material to deliver attractive and functional upholstery solutions.

PU leather sofas bring a luxurious touch to living spaces. The material offers a smooth, uniform finish that resists fading and cracking. Homeowners choose PU leather sofas for their modern appearance and easy upkeep. Spills and stains can be wiped away quickly, making these sofas ideal for busy households. The cost advantage of PU leather allows more consumers to enjoy the look of leather furniture without the high investment.

Dining chairs and office seating often feature PU leather upholstery. This choice provides comfort and style in both residential and commercial settings. PU leather chairs resist wear from daily use and maintain their appearance with minimal effort. The material’s flexibility supports ergonomic designs, enhancing user comfort during extended periods of sitting.

|

Feature |

PU Leather Advantage |

|---|---|

|

Cruelty-Free |

No animal products used |

|

Affordable |

Lower cost than real leather |

|

Easy Care |

Simple cleaning and upkeep |

|

Style |

Wide range of colors/finishes |

PU leather stands out as a cost-effective and ethical alternative to genuine leather. Its widespread use in fashion and upholstery demonstrates its ability to meet the demands of modern consumers. The combination of style, affordability, and easy care ensures PU leather remains a top choice in today’s market.

PU material shapes modern living by enhancing comfort, durability, and performance in products such as furniture, footwear, and construction materials. The table below highlights how its flexibility, lightweight nature, and insulation properties benefit daily life:

|

Application Area |

Key Properties |

Benefits |

|---|---|---|

|

Furniture |

Flexibility, durability, lightweight |

Comfort, long-lasting support |

|

Footwear |

Lightweight, cushioning |

Style, comfort |

|

Construction |

Insulation, energy efficiency |

Temperature control, savings |

Despite its advantages, consumers should consider environmental impacts and health concerns, including non-biodegradability and chemical exposure. Ongoing innovations, such as bio-based and non-isocyanate polyurethanes, promise safer and more sustainable solutions. Recognizing these factors helps individuals make informed choices about the products they use every day.

PU material consists of polymers created by reacting polyols with diisocyanates. Manufacturers use this process to produce flexible, rigid, or foam forms. Polyurethane adapts to many applications due to its customizable chemical structure.

Polyurethane meets safety standards for consumer products. Manufacturers test PU for toxicity and allergen levels. Most household items containing PU pose minimal health risks when used as intended.

PU leather offers a cruelty-free alternative to animal leather. It resists stains and water, costs less, and requires less maintenance. Natural leather provides greater breathability and longevity, but PU suits many fashion and upholstery needs.

Recycling PU material presents challenges due to its chemical structure. Some facilities process PU foam and coatings, but most end up in landfills. Researchers continue to develop new recycling methods for polyurethane products.

PU material rarely triggers allergic reactions. Its dense structure blocks dust mites and common allergens. Sensitive individuals should check product labels for additives or coatings that may cause irritation.

Polyurethane does not biodegrade easily. Disposal in landfills contributes to environmental waste. Manufacturers now explore bio-based and non-isocyanate PU options to reduce ecological impact.

Consumers encounter PU material in furniture, bedding, footwear, automotive parts, insulation, medical devices, and fashion accessories. Polyurethane enhances comfort, durability, and performance in these products.

Tip: Always check product labels for PU content to make informed purchasing decisions.

|

PU Application |

Common Products |

|---|---|

|

Furniture |

Sofas, chairs |

|

Footwear |

Sneakers, boots |

|

Fashion |

Jackets, bags |

|

Construction |

Insulation panels |

|

Medical |

Catheters, tubing |