-

Tel : +8618150976625

-

Email : Hello@MicrofiberLeather.com

Tel : +8618150976625

Email : Hello@MicrofiberLeather.com

I have seen how real leather soccer balls come to life inside the Soccer Leather Factory. Workers pick the best leather, cut it into perfect panels, and stitch each piece with care. I watch as they insert the bladder and check every ball for quality. Their attention to detail and skill make these balls stand out from synthetic ones. The process combines tradition and expert technique, creating soccer balls that last and feel truly authentic.

Choose full-grain leather for soccer balls. It lasts longer and feels better on the field.

Look for hand-stitched balls. They offer better durability and an authentic playing experience.

Understand bladder types: latex provides a soft feel, while butyl retains air longer.

Inspect soccer balls for smooth seams and consistent surfaces. Quality checks ensure better performance.

Embrace the blend of tradition and technology in ball-making. It enhances quality and sustainability.

I always start my journey in the factory by searching for the best leather. The workers and I inspect each hide with care. We look for smooth surfaces, consistent thickness, and minimal blemishes. Only full-grain leather passes our strict standards. This type of leather comes from the top layer of the hide, which gives the ball its strength and natural feel.

Tip: Full-grain leather lasts longer and feels better on the field. I recommend checking for this when buying a soccer ball.

I watch as the team sorts the hides. They separate the premium pieces from the rest. We use a checklist to make sure every hide meets our requirements:

No deep scars or holes

Even color and texture

Proper thickness for durability

The selection process sets the foundation for a high-quality soccer ball. I believe that the right leather makes all the difference.

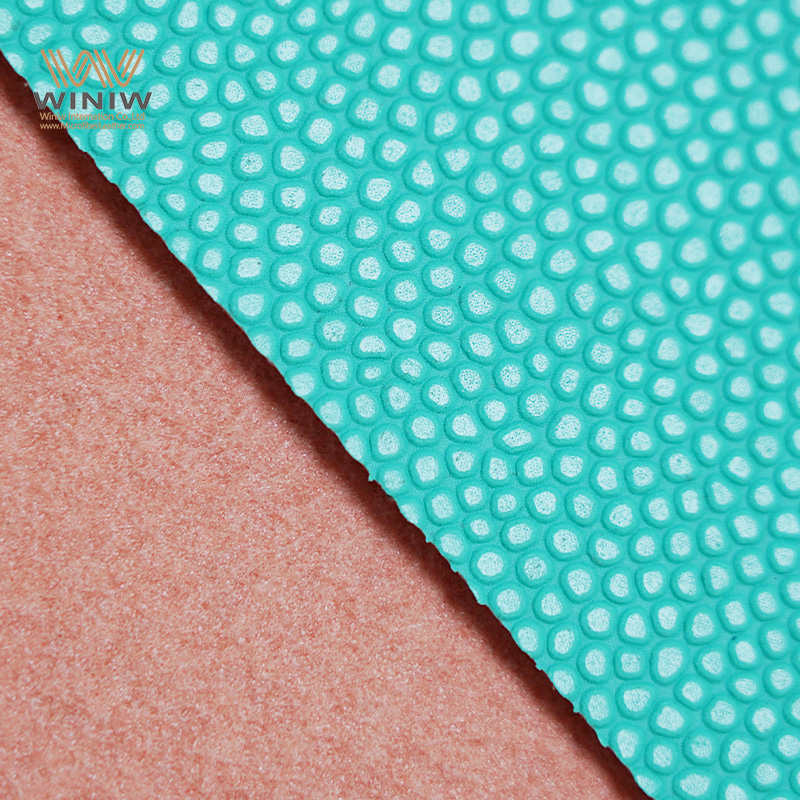

After we select the leather, we treat it to improve its performance. The factory uses natural oils and waxes to condition the hides. This step keeps the leather flexible and water-resistant. I see the workers apply these treatments by hand, making sure every inch gets covered.

Once the leather is ready, we move to panel cutting. The factory uses steel dies to stamp out geometric shapes, usually hexagons and pentagons. I notice that precision matters here. Each panel must match the others in size and shape. The team arranges the panels on a table and checks them against a template.

|

Step |

Purpose |

|---|---|

|

Conditioning |

Adds flexibility |

|

Cutting |

Ensures uniform panels |

I find that careful treating and cutting help the ball keep its shape and feel. The process requires skill and attention to detail. I admire how the workers combine tradition with modern tools to prepare the leather for stitching.

When I walk through the factory, I see workers arranging leather panels in different shapes. Most traditional soccer balls use a combination of hexagons and pentagons. These shapes fit together to form a nearly perfect sphere. I notice that the number and shape of panels can change how the ball performs on the field.

Some modern balls, like the Adidas Teamgeist, use a 14-panel design. This design stands out because it uses curved and interlocking panels instead of the usual flat shapes. The Teamgeist ball feels smoother in my hands. The reduced number of seams means less water can get inside, which helps the ball last longer. The roundness and flight consistency improve because the surface has fewer corners and edges. I see that players get better control and more predictable movement during a game.

Note: The shape and arrangement of panels affect how the ball moves, how it feels when kicked, and how long it lasts.

I always check that each panel matches the template exactly. Even a small mistake can change the way the ball flies or bounces. Precision in cutting and arranging panels is one of the secrets to making a great soccer ball.

I often watch workers stitch panels together. Some use sewing machines, while others use needles and thread by hand. Machine stitching works fast and gives a neat finish. Many factories use machines for synthetic balls or lower-cost options. Machines can also bond panels with heat or glue, which creates a seamless look.

Hand-stitching takes more time and skill. I see workers push thick needles through tough leather, making tight and even stitches. They use waxed polyester thread, which holds up well against wear and tear. Each stitch must be strong and straight. If a stitch is too loose, the ball can lose its shape. If it is too tight, the leather might tear.

I believe hand-stitching gives the ball a special quality. The seams feel stronger and the panels stay in place longer. High-end leather balls almost always use hand-stitching. This method keeps the ball round and helps it keep its bounce. I notice that professional players prefer hand-stitched balls because they trust the durability and feel.

Tip: If you want a soccer ball that lasts and feels authentic, look for one that is hand-stitched.

Here is a quick comparison:

|

Stitching Method |

Speed |

Durability |

Feel |

Cost |

|---|---|---|---|---|

|

Hand-Stitching |

Slow |

Very High |

Authentic |

Higher |

|

Machine Stitching |

Fast |

Moderate |

Consistent |

Lower |

|

Bonding |

Fastest |

Varies |

Seamless |

Moderate |

I always admire the patience and skill of the hand-stitchers. Their work gives each ball a unique touch that machines cannot match. When I hold a hand-stitched leather ball, I feel the tradition and care that went into making it.

When I reach the bladder station in the factory, I see how important this part is for the soccer ball. The bladder holds the air and gives the ball its bounce. I notice that the workers use two main types of materials: latex and butyl.

Latex bladders feel soft and give the ball a natural bounce. Many professional balls use latex because players like the touch and response. However, latex can lose air faster, so it needs to be pumped up more often.

Butyl bladders keep air much longer. I see these in training balls and some match balls. Butyl feels a bit firmer, but it makes the ball easier to maintain.

Here is a quick comparison:

|

Bladder Type |

Air Retention |

Feel |

Common Use |

|---|---|---|---|

|

Latex |

Low |

Soft, lively |

Pro match balls |

|

Butyl |

High |

Firm |

Training, matches |

Tip: If you want a ball that stays inflated longer, choose one with a butyl bladder.

After the workers choose the right bladder, they insert it into the stitched leather shell. I watch as they carefully push the bladder through a small opening. They make sure it sits evenly inside the ball. This step matters because a twisted or folded bladder can ruin the ball’s shape.

Next, the workers seal the opening. Some use strong glue, while others stitch it closed by hand. I see them inflate the ball to the correct pressure. They roll and press the ball to make sure the bladder fills every corner. This helps the ball stay round and gives it a true bounce.

Sometimes, the workers use a special mold to shape the ball as it dries. The mold holds the ball in place and keeps it perfectly round. I notice that this step makes a big difference in the final product.

Note: Proper sealing and shaping help the ball last longer and perform better on the field.

I always admire how much care goes into this stage. The right bladder and careful shaping turn a stitched shell into a real soccer ball.

I always begin the final stage by looking closely at each soccer ball. My eyes scan for any flaws in the leather, such as uneven color, scratches, or loose stitches. Workers at the Soccer Leather Factory use bright lights to spot even the smallest imperfections. We check every seam and panel to make sure the ball looks perfect. I run my hands over the surface to feel for bumps or rough spots. If I find a problem, I set the ball aside for repairs. This careful inspection helps us deliver only the best balls to players.

Tip: A high-quality soccer ball should have smooth seams and a consistent surface. If you see wrinkles or gaps, the ball may not perform well.

I also check the logo and markings. They must be clear and centered. The ball should look professional and ready for the field.

After the visual check, I move on to testing how the ball performs. I use a pump to inflate the ball to the recommended pressure. I watch how well it holds air over time. If the ball loses pressure quickly, it does not pass the test.

I also test how much water the ball absorbs. I dip the ball in water and weigh it before and after. Too much water makes the ball heavy and hard to play with. I want the ball to stay light, even in wet conditions.

To check shape retention, I kick and bounce the ball repeatedly. I look for changes in roundness. A good ball keeps its shape after many uses. I also test rebound by dropping the ball from a set height and measuring how high it bounces.

Here is a summary of the main tests I perform:

|

Test Type |

Description |

|---|---|

|

Pressure Loss |

Ensures the ball maintains its pressure during play. |

|

Water Absorption |

Measures how much water the ball absorbs, affecting its weight and performance. |

|

Shape Retention |

Tests the ball's ability to maintain its shape after repeated use. |

|

Rebound Characteristics |

Evaluates how well the ball bounces back after being struck. |

I believe these tests guarantee that every ball from the Soccer Leather Factory meets high standards. Players can trust the ball to perform well in any game.

When I walk through the Soccer Leather Factory, I see skills that machines cannot replace. The workers use steady hands and sharp eyes to inspect every piece of leather. They know how to spot the smallest flaw. I watch them cut panels with precision, making sure each one fits perfectly. The stitching process shows true craftsmanship. Some workers use traditional hand-stitching, passing thick needles through tough leather. They create tight, even seams that hold the ball together for years.

I notice that every worker takes pride in their craft. They do not rush. They check their work at every step. This careful attention gives each ball a unique character. No two balls feel exactly the same. The Soccer Leather Factory values tradition. The team uses techniques passed down through generations. I believe this dedication sets these balls apart from mass-produced synthetic ones.

🏆 Tip: Hand-stitched leather balls often last longer and offer a more authentic playing experience.

The factory also uses natural treatments for the leather. Workers apply oils and waxes by hand. This step keeps the leather soft and water-resistant. I see how these small details make a big difference on the field.

While tradition matters, the Soccer Leather Factory also embraces new technology. I have seen how automation helps with quality control. Machines scan each ball for defects in real time. This process catches problems early and keeps production running smoothly. The factory uses predictive maintenance tools to reduce downtime. When a machine needs attention, the system alerts the team before a breakdown happens.

Material science has changed the way we make soccer balls. The factory now uses eco-friendly treatments and sources leather from sustainable farms. I see new materials that make the balls more durable and better for the environment. Players want high-performance balls, but they also care about sustainability. The Soccer Leather Factory listens to these concerns and adapts.

One of the most exciting changes is digital integration. Some balls now have tiny sensors inside. These sensors track speed, spin, and impact. Coaches and players use this data to improve their skills. I believe this technology opens new doors for training and competition.

Here are some of the latest advancements I have seen in the Soccer Leather Factory:

Automation for real-time quality checks and predictive maintenance

Eco-friendly and durable materials for better performance and sustainability

Embedded sensors for tracking ball performance and player stats

📈 Note: Technology and tradition work together to create the best soccer balls.

The Soccer Leather Factory stands out because it blends old and new methods. The team respects the art of handcrafting but also uses the latest tools. This balance creates soccer balls that feel authentic and perform at the highest level. I trust the process because I see the results every day.

I have seen every step that goes into making a real leather soccer ball. The Soccer Leather Factory team selects the best leather, cuts precise panels, and stitches each ball with care. These balls last longer than most synthetic ones, as shown below:

|

Type of Football |

Average Lifespan |

|---|---|

|

A few months to several years |

|

|

Real Leather |

Generally longer than synthetic |

I also learned that real leather balls have a higher carbon footprint and use more water, but they are biodegradable and last longer.

|

Aspect |

Real Leather |

Synthetic Leather |

|---|---|---|

|

Carbon Footprint |

Higher due to animal agriculture and tanning |

Lower during production |

|

Water Usage |

Approximately 240 liters per square meter for tanning |

Less water used |

|

Biodegradability |

Biodegradable and lasts longer |

Not biodegradable, relies on non-renewable resources |

I appreciate the balance of tradition and new technology at Soccer Leather Factory. I hope you now see the value in authentic soccer balls and the skill behind every one.

I check the texture and smell. Real leather feels soft and has a natural grain. It often smells earthy. Synthetic balls feel smoother and sometimes have a plastic scent.

I notice that hand-stitched leather balls offer better touch and control. The seams stay tight, and the ball keeps its shape longer. Players trust these balls for important matches.

I always wipe my ball with a damp cloth after use. I store it in a cool, dry place. I avoid soaking it in water. Regularly applying leather conditioner keeps it soft and flexible.

I use my leather ball in light rain, but I avoid heavy downpours. Water can damage untreated leather. Many modern leather balls have water-resistant coatings, but I still dry them after play.

I see that real leather costs more than synthetic materials. Skilled workers spend hours hand-stitching each ball. The quality, durability, and craftsmanship raise the price.