The difference between Microfiber Leather and PU Leather

Jul 12, 2022

Microfiber leather and ordinary PU difference, this is a lot of consumers are very concerned about the problem, today for you to explain.

The difference in price. At present, the general price range of ordinary PU leather on the market is 15-30 meters, while the general price range of microfiber leather is 50-150 meters, so the price of microfiber is several times that of ordinary PU.

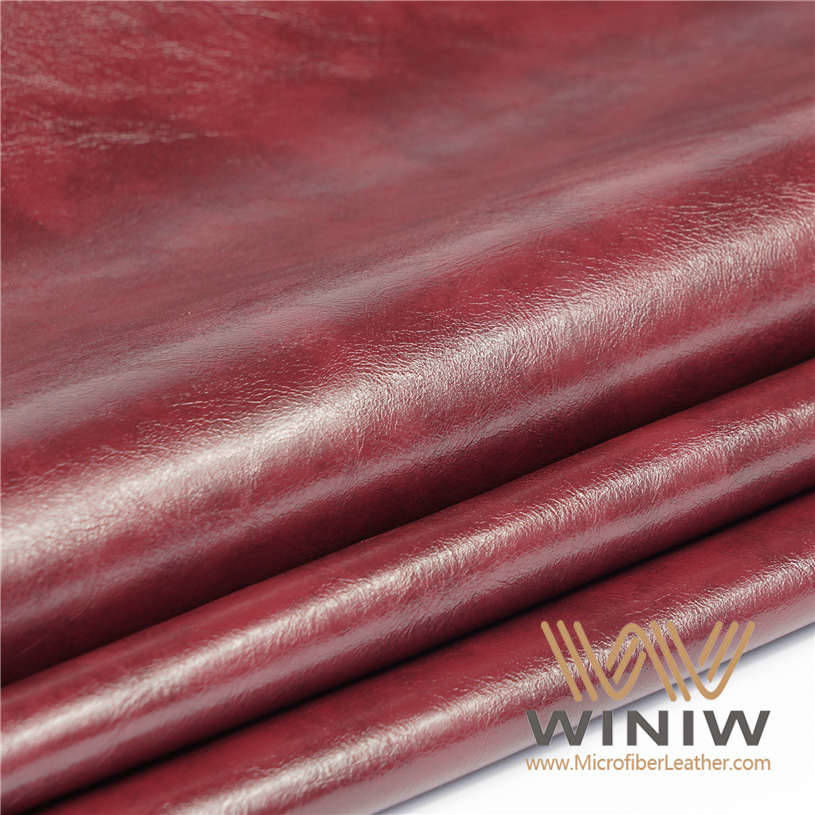

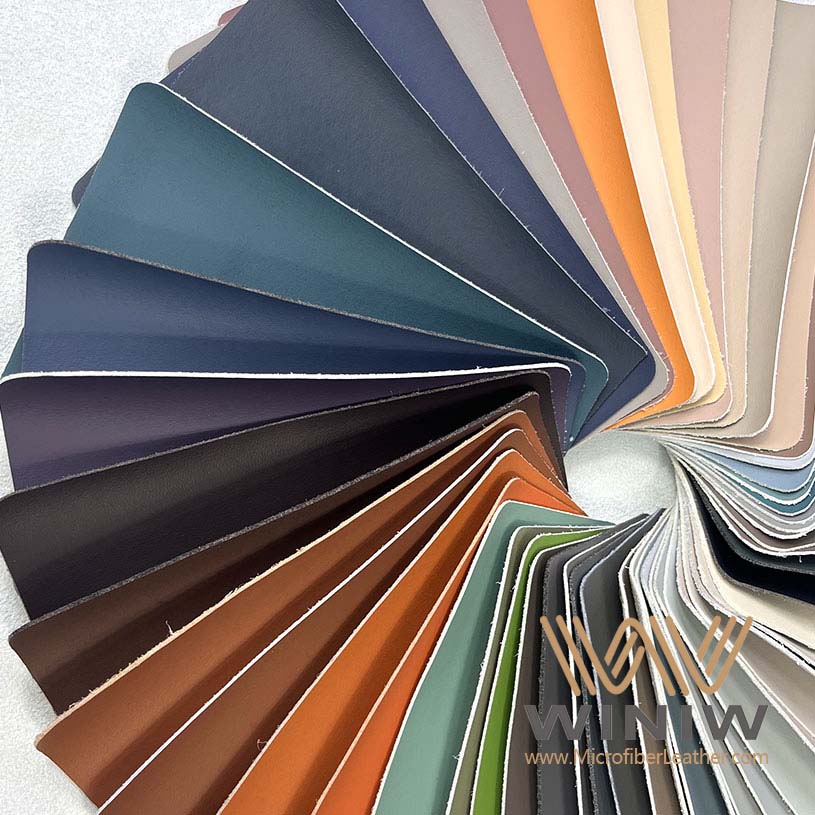

The surface performance is different. Although the surface layer of microfiber leather and ordinary PU are polyurethane resin, and ordinary PU popular for many years will be much more in color and style than microfiber leather. But generally speaking, the polyurethane resin on the surface of microfiber skin has stronger wear resistance, acid and alkali resistance, hydrolysis resistance, and color fastness and texture than ordinary PU.

The fabric material is different. Ordinary PU is made of knitted fabric, woven fabric or non-woven fabric and coated with polyurethane resin. Microfiber skin is made of microfiber non-woven fabric with three-dimensional structure and coated with high-performance polyurethane resin. The difference of substrate material, technology and technical level has a decisive effect on the properties of microfiber leather.

Different performance. Microfiber leather is superior to ordinary PU in strength, wear resistance, moisture absorption, comfort and other performance indicators. In layman's terms, it's more like leather, more durable, and feels better.

Market prospect. Due to the low technical threshold, serious excess capacity and fierce competition in the general PU market, the products are reduced in production and materials, which is incompatible with the increasingly upgraded consumption concept, and the market prospect is worrying. However, due to the high technical threshold and limited production capacity, the product performance is increasingly recognized by consumers, and the market has a large space to rise.

Microfiber leather and PU represent the products of synthetic leather in different development stages and different technical levels, so they have a certain substitution effect. It is believed that with the recognition of more and more people, microfiber leather will be more widely used in all aspects of human life.