Commonly Used Raw Materials for Garments Leather

Mar 09, 2023

Mink

Generally mink is a very noble leather, less used in handbag design, usually used in clothing. There are two kinds of mink, American mink and European mink. The benefits are that the mink skin is rarely disabled, the mink skin is of average size and thickness, the fur is evenly distributed, and the color difference is small. There are also considerable differences between the fur of male and female mink. Male mink fur is big and thick, and the coats made from it have a sense of weight, while female mink is softer and lighter to wear, with more usage. The female mink has a narrower and smaller body, shorter hair, fine and lighter hair, long and lustrous surface hair, and more expensive finished products. Generally speaking, the female mink is good, but also according to the preferences of the buyer and with the style and choice.

Pigskin

Because the pig hair through the skin layer directly to the inner layer, so the pigskin breathability and moisture absorption than cowhide good. But the pores are coarse, into the "Pin" type, rough skin pattern, not as beautiful as cowhide, need to be processed to change the shortcomings. Yellow cowhide epidermis is thin, and hair is not dense, hair root into not deep. Skin to, fat glands, sweat glands are not developed, generally used for shoes, leather bags surface. Features: the thickness of pigskin, elastic enough. Buffalo hide hair is sparse, sticky surface rough, there are obvious papillary bumps and folds, the texture of the leather plate is more withered and thin, large and heavy area. Commonly used in making shoes and mechanical wheel belt, after processing to become soft before you can make bags.

Sheepskin

Goat skin fiber organization is more solid, soft and elastic good. Similar to the yellow cowhide, but thinner, the skin surface of the concave and convex lines clear, detailed, strong sense of leather. Sheepskin is similar to goatskin, but the hair bundle of fat glands, sweat glands are more numerous, made of manufactured products, especially soft, stretchy, feel like velvet, but low strength, easy to rot, can only do leather clothing, gloves, can not do shoe uppers and handbags.

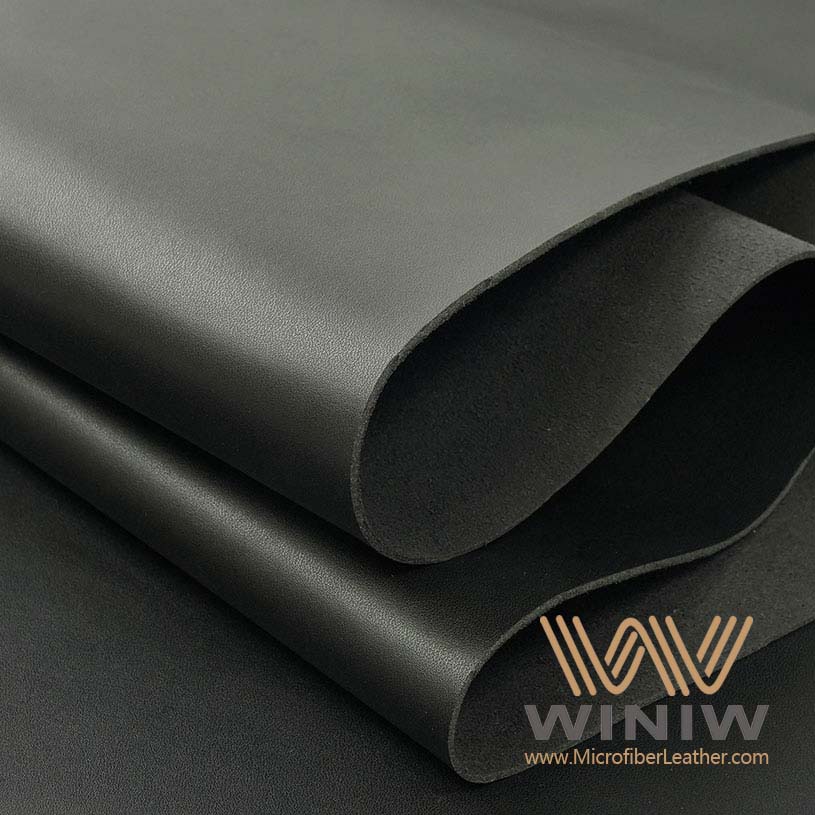

PU leather

PU leather is a kind of artificial leather, is the English "ploy urethane", chemical Chinese name "polyurethane". He has excellent wear resistance, excellent cold breathability, and cheap, has become the most popular material for making leather clothing in recent years. And PU leather without the odor of leather, can be washed, easy to maintain, in line with international environmental requirements and composition standards, is a new generation of fashion fabrics. And PU leather is artificial leather, more in line with the love of animals, people and nature in harmony with modern values.

If you are interested PU Leather for Garments Leather, please contact winiwpuleather at www.winiwpuleather.com.